Keeping It Cool at Huntington Center

CHALLENGE:

The Huntington Center is a state-of-the-art, multi purpose arena in downtown Toledo, Ohio. It is home to the Toledo Walleye hockey team as well as a venue for major concerts, sporting events, and entertainment shows. It is one of the nation’s first LEED certified professional sports arenas, taking great pride in being “green” in both design and operation. Utilizing industrial ammonia chillers at the Huntington Center was a perfect green solution as they are efficient, ozone safe, and cost-effective. However, working with ammonia refrigeration can be dangerous and requires both a separate storage room and special training to ensure the OSHA regulations are followed. Additionally, because the chillers are used so frequently to transition from one event to the next, it was imperative to find a local, knowledgeable, and trained team to provide preventative maintenance, including the ability to overhaul and rebuild industrial chillers.

SOLUTION:

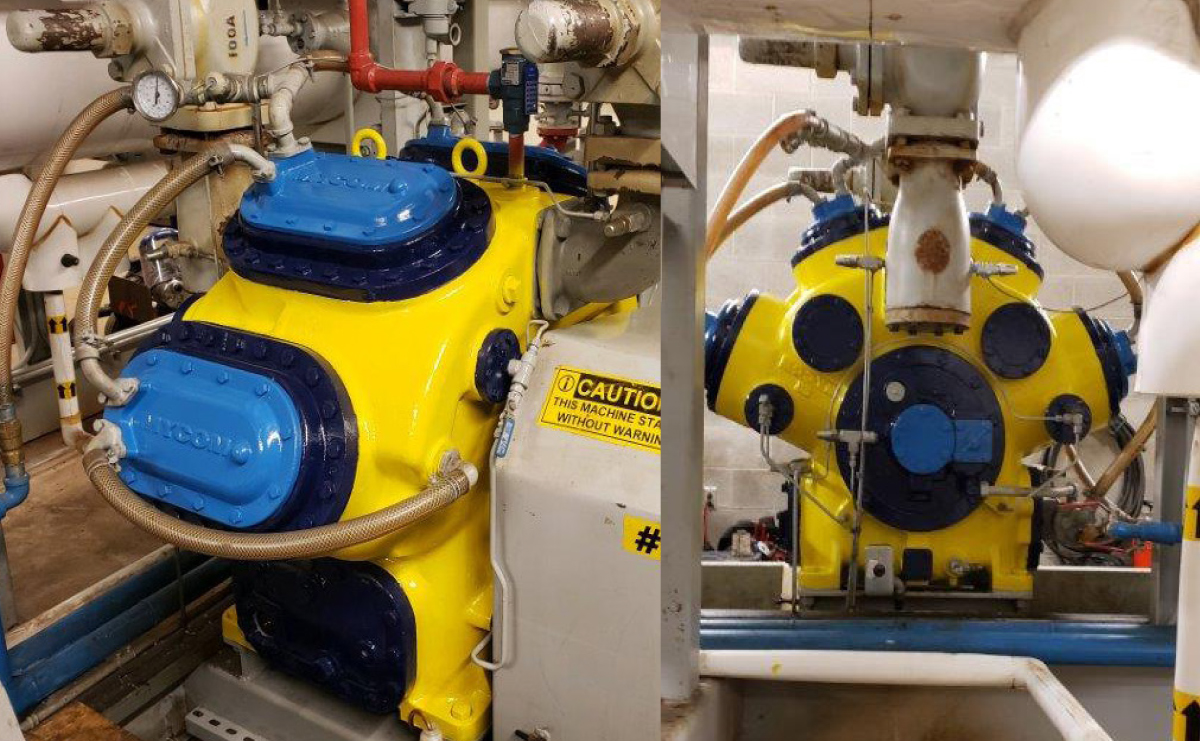

Campbell, Inc., located within 10 miles of Huntington Center, has over 50 years of experience in providing preventative maintenance of industrial chillers. The maintenance schedule of industrial chillers involves more than just an inspection. The units need to be overhauled and rebuilt after so many uses. Additionally, those working with ammonia must be properly credentialed and our technicians are specially trained and Campbell maintains a membership IIAR (International Institue of Ammonia and Refrigeration). Once the rebuild of the chillers was complete, Campbell added a fun element by painting the chillers in the Walleye team colors of blue, gold, and white. While to the average observer, the colors are just fun, the fresh paint also indicates that the chillers have had a recent overhaul and the bright colors help to quickly identify any leakage for faster troubleshooting.

BENEFIT:

Working with a local company is a cost-effective solution when chillers need to be maintained as often as the Huntington Center units require. When inspecting and maintaining industrial ammonia chillers, Campbell technicians can use their preventive maintenance expertise as a foundation for determining the overhaul and rebuild of industrial chillers. With many strategic partners in Ohio and Michigan, Campbell can quickly secure new or used parts when needed. This not only keeps shipping costs down but allows for recycling of quality equipment when parts meet ASHRAE life expectancy of 80-90%. Reusing equipment not only makes financial sense, but it also keeps viable equipment out of landfills and junkyards. In addition, Campbell can provide preventative maintenance, installation, and service for all types of chillers including centrifugal chillers, air-cooled chillers, and air-cooled screw machines.

Since 1968, Campbell, Inc. has been helping building owners and managers with design, engineering, installation, maintenance and repair of their HVAC systems. Our experience tracking energy usage patterns and implementing the latest technologies for heating, ventilation and air conditioning systems means you will achieve maximum efficiency from your HVAC investment. Campbell, Inc. provides energy saving solutions for all types of heating, ventilation and air conditioning systems. We specialize in Commercial, Industrial, Institutional and Large Retail Facilities.